Engineering controls include proper laboratory design, adequate ventilation, and the use of other safety devices. These controls offer the first line of protection and are highly effective in that they generally require minimal special procedures.

- Isolation

- Reduce or remove hazards by separation in time or space. (May be particularly helpful in a shared lab space where different types of chemicals or biohazards are being used.)

- Enclosure

- Place the material or process in a closed system. (e.g., Schlenk line or glovebox)

- Transportation

- Move hazardous materials where fewer workers are present.

- Guarding and shielding

- Install guards to provide protection from moving parts or electrical connections.

- Shielding provides protection from potential explosions.

- Ventilation

- Use of fume hoods, snorkels, biological safety cabinets, and air filters.

Ventilation is the most common and most important form of engineering control used to reduce exposures to hazardous chemicals.

General Lab Ventilation

The primary functions of laboratory ventilation systems are to provide safe, comfortable, breathable environments for all lab users, and to minimize exposures to hazardous air contaminants. General ventilation must not be relied on to control chemical vapors, gases, and mists.

Chemical Fume Hoods

Fumes hoods are used for laboratory work with materials that do not require special handling procedures. A general fume hood can be one of four types:

- Constant Air Volume (CAV) or Conventional Hood, the basic hood with a movable sash and baffle. This hood is generally the least expensive and its performance depends mainly on the position of the sash due to the fact that the amount of air exhausted is constant. The face velocity of a CAV hood is inversely proportional to the sash.

- By-Pass Hood, designed to allow some exhaust air to "by-pass" the face of the hood even when the sash is closed. It is designed for use with sensitive and fragile apparatus and/or instruments.

- Auxiliary Air Hood, designed to introduce outside air into the hood and limit the amount of room air that is exhausted.

- Variable Air Volume (VAV) Hood, designed to regulate the hood exhaust and keep the air velocity at a predetermined level. VAV hoods are designed to use less energy than CAV.

The majority of fume hoods on campus are VAV hoods with air flow monitors on the side panels. Some of the older fume hoods are campus are CAV hoods. Make sure that you know which one you are working with and to follow proper protocols while using a fume hood at all times.

Fume hood inspection and testing program

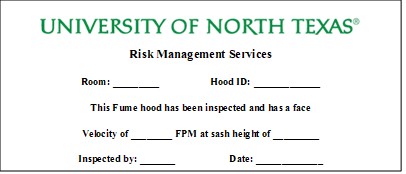

RMS performs an annual functional performance test to assure hoods perform as required. The performance test typically includes an evaluation of the face velocity, and airflow monitors. RMS may also note any observed problem with controls, sash, baffles, plumbing, light or corrosion.

Fume hoods tested by RMS will have a label that records its inspection history. If in between the annual testing the fume hood alarm goes off or there are other issues with the fume hood, submit a work request to the UNT Facilities and notify RMS.

General safety practices

Please see this video explaining the components of a chemical fume hood, how a fume hood works, and how to use it. To ensure safety and proper fume hood performance, follow these guidelines:

- Use a fume hood when working with chemicals or procedures that may produce hazardous fumes or vapors.

- Know how to properly operate a fume hood before beginning work. Inspect the fume hood before starting each operation to ensure it is working.

- Place equipment and chemicals at least six inches behind the fume hood sash. This practice reduces the chance of exposure to hazardous vapors.

- Do not allow paper or other debris to enter the exhaust duct of the hood.

- Do not store excess chemicals or equipment in fume hoods.

- Do not block the baffle area of the fume hood.

- Elevate any large equipment within the hood at least three inches to allow proper ventilation around the equipment.

- When working in a fume hood, set the sash at the height indicated by the arrow. The only time the sash should be completely open is while setting up equipment.

- Do not alter/modify the fume hood or associated ductwork.

- Clean up spills in the hood immediately.

- Do not ignore or defeat fume hood flow alarms. Submit a work request to the UNT Facilities and notify RMS.

- Fume hoods may fail for a variety of reasons. Lab personnel should have a contingency plan for hood failure to prevent development of hazardous conditions, and to avoid interruptions in laboratory use.

Glove Boxes

A glove box consists of a working enclosure containing a controlled atmosphere, an airlock to enable items to be taken in and out of the box, a transparent front to allow the worker to observe the interior of the box, and gloves (usually butyl rubber) sealed into the front, to allow working access into the interior. Positive pressure glove boxes are good for protecting the items in the box from the external atmosphere, as any leak is out of the box, preventing air from entering.

All personnel using a glove box should follow the following recommendations:

- All personnel must receive documented training from the PI or delegate before any work in a glove box occurs. All trained personnel must understand the design features and limitations of a glove box before use. The training must include detailed instruction on elements such as the ventilation and vacuum controls that maintain a pressure differential between the glove box and outside atmosphere, atmospheric controls (e.g., controlling oxygen concentrations and moisture), etc.

- Prior to use, a visual glove inspection must be performed. Changing of a glove must be documented (date, manufacturer, model of glove, and person performing change). Gloves should not be used until they fail; they should be changed according to the glove box manufacturer's recommendations or whenever necessary.

- Plugging ports that are never or infrequently used is recommended. A properly plugged port should have a stub glove and a glove port cap installed.

- Chemical resistant gloves (e.g., disposable nitrile gloves) should be used under the glove box gloves to protect from contamination.

- The glove box pressure must be checked every day, before use and immediately after gloves are changed. The pressure check must be documented.

- Keep sharps in an approved container while in the glove box.

- Follow all safe work practices for using and handling compressed gas that may be associated with working in the glove box.

- All equipment and chemicals in the glove box must be organized and all chemicals must be labeled. Do not allow items, particularly chemicals to accumulate in the glove box.

For more information on the use of a glovebox, see Appendix L.

Biosafety Cabinets

A biosafety cabinet is an enclosed, ventilated laboratory workspace for safely working with materials contaminated with (or potentially contaminated with) infectious materials. The primary purpose of a biosafety cabinet is to serve as a means to protect the laboratory worker and the surrounding environment from pathogens. All exhaust air is filtered as it exits the biosafety cabinet, removing harmful particles. Biological safety cabinets are not designed to be used with chemical applications so the use of chemicals should be kept to a minimum. Applications that involve the use of chemicals should be conducted in chemical fume hoods. Refer to the Biosafety Cabinets (BSC) Guidance for more details on the use of biosafety cabinet.

Snorkel Hoods

Snorkel hoods are small fume exhaust duct connections. They are designed with flexible ducts and can be positioned directly over a work area at the bench. See this video for demonstration on snorkels. For best performance, the snorkel hood should be placed within six inches of the item needing ventilation. Snorkel hoods should only be used to exhaust heat and nuisance odors. They should never be used with highly toxic or flammable chemicals.