Flammable and Combustible Liquids

Flammable liquids are among the most common chemicals found in a laboratory. The primary hazard associated with flammable liquids is their ability to readily ignite and burn. The vapor of a flammable liquid, not the liquid itself, can ignite and start a fire. Do not heat flammable liquids on a hot plate or open flame. Heat and transfer flammable liquids in well-ventilated areas or fume hoods. These substances should be stored separately from oxidizers and corrosive materials and in a flammable storage cabinet. Lab allowable quantity limits are determined by a complex mixture of data points including the flash point of the liquid, the occupancy classification of the laboratory, the number of fire control areas, the use of flammable cabinets, the presence of sprinklers, and the floor number. A good rule of thumb is that storage of flammable liquids in approved flammable storage cabinets and should not exceed 10 gallons; however, exceptions may apply.

The OSHA Laboratory Standard defines a flammable liquid as any liquid having a flashpoint below 100 °F, except any mixture having components with flashpoints of 100 °F or higher, the total of which make up 99% or more of the total volume of the mixture.

Flashpoint is defined as the minimum temperature at which a liquid gives off enough vapor to ignite in the presence of an ignition source. The risk of a fire requires that the temperature be above the flashpoint and the airborne concentration be in the flammable range above the Lower Explosive Limit (LEL) and below the Upper Explosive Limit (UEL).

The OSHA Laboratory Standard defines a combustible liquid as any liquid having a flashpoint at or above 100 °F, but below 200 °F, except any mixture having components with flashpoints of 200 °F, or higher, the total volume of which make up 99% or more of the total volume of the mixture. OSHA further breaks down flammables into Class I liquids, and combustibles into Class II and Class III liquids. Please note this classification is different than the criteria used for DOT classification. This distinction is important because allowable container sizes and storage amounts are based on the particular OSHA Class of the flammable liquid.

| Classification | Flash Point | Boiling Point |

| Flammable Liquid | ||

| Class IA | <73 °F | <100 °F |

| Class IB | <73 °F | ≥ 100 °F |

| Class IC | ≥73 °F, <100 °F | >100 °F |

| Combustible Liquid | ||

| Class II | ≥100 °F, <140 °F | -- |

| Class IIIA | ≥140 °F, < 200 °F | -- |

| Class IIIB | ≥200 °F | -- |

Flammable and combustible liquids are one of the most common types of chemicals used at the University and are an important component in a number of laboratory processes. In addition to the flammable hazard, some flammable liquids also may possess other hazards such as being toxic and/or corrosive. While common, it is important to remember that these materials can constitute a significant immediate threat and should be treated with particular care.

- Flammable liquids that are not in active use should be stored inside fire resistant flammable storage cabinets or safety cans.

- Flame-resistant laboratory coats must be worn when working with flammable materials and/or with procedures where a significant fire risk is present (e.g., when working with open flame, etc.).

- Always keep flammable liquids stored away from oxidizers and away from heat or ignition sources such as vacuum pumps, radiators, electric power panels, etc.

- When using flammable liquids, keep containers away from open flames; it is best to use heating sources such as steam baths, water baths, oil baths, and heating mantels. Never use a heat gun to heat a flammable liquid.

- Any areas using flammables should have a fire extinguisher present. If a fire extinguisher is not present, then contact RMS at 940-5652109.

- When pouring flammable liquids, it is possible to generate enough static electricity to cause the flammable liquid to ignite. If possible, make sure both containers are electrically interconnected to each other by bonding the containers, and connecting to a ground (see Bonding and Grounding below).

- Always clean up any spills of flammable liquids promptly. Be aware that flammable vapors are usually heavier than air (vapor density > 1). For those chemicals with vapor densities heavier than air (applies to most chemicals), it is possible for the vapors to travel along floors and, if an ignition source is present, result in a flashback fire.

- Certain flammable solvents such as ethyl ether, isopropyl ether, dioxane, tetrahydrofuran will form peroxides which explode if allowed to concentrate by evaporation or by distillation (see Peroxide Forming Compounds). Improper handling of most flammable liquids can lead to health hazards - skin reactions and inhalation illnesses.

Flammable Solids

Flammable solids are solids which are readily combustible, or may cause or contribute to a fire through friction. Readily combustible solids are powdered, granular, or pasty substances which are dangerous if they can be easily ignited by brief contact with an ignition source. Flammable solids are more hazardous when widely dispersed in a confined space (e.g., finely divided metal powders).

Storage Guidelines

Flammable Storage Cabinets

All flammable liquids not in use should be kept in the flammable liquid storage cabinet. Venting of flammable cabinets is NOT required, however, if a flammable cabinet is vented, it must be vented properly according to the manufacturer's specifications and NFPA 30. Typically, proper flammable cabinet ventilation requires that air be supplied to the cabinet and the air be taken away via non-combustible pipes. If you are planning on venting your flammable storage cabinet, please contact RMS at 940-565-2109 for more information.

Combustible materials like paper and packaging nylon bags should never be stored inside of flammable cabinets or near flammable liquids or solids. Always segregate flammable or combustible liquids from oxidizing acids and oxidizers.

Flammable Storage in Refrigerators/Freezers

Standard refrigerators or freezers must never be used to store flammable liquids. Standard refrigerators are not electrically designed to store flammable liquids. Store flammable liquids only in specially designed flammable storage refrigerators/freezers or explosion-proof refrigerators/freezers.

Properly rated flammable liquid storage refrigerators/freezers have protected internal electrical components and are designed for the storage of flammable liquids. Explosion-proof refrigerators/freezers have both the internal and external electrical components properly protected and are designed for the storage of flammable liquids. Refrigerators and freezers rated for the storage of flammable materials will be clearly identified as such by the manufacturer.

Handling Guidelines

- Handle flammable and combustible substances only in areas free of ignition sources and use the chemical in a fume hood whenever practical.

- Only the amount of material required for the experiment or procedure should be stored in the work area.

- Always transfer flammable and combustible chemicals from glass containers to glassware or from glass container/glassware to plastic.

- Flammable liquids in a metal dispending container should always be bonded and grounded

when pouring or dispending liquid to prevent the buildup of static electricity and

prevent the formation of sparks which will cause a fire.

- Dispensing flammable liquids that have a flash point < 100 °F or ignitable liquids > 100 °F when heated above their flashpoint, from one container to another can generate static electricity and must be bonded and grounded.

- If you must transfer a Class 1A flammable chemical (e.g., diethyl ether, pentane) from a metal container make sure that the equipment is bonded and grounded (See below for information on bonding and grounding).

- Flame-resistant laboratory coats must be worn when working with any number of pyrophoric

materials, when working with large quantities (1 liter or more) of flammable materials,

and/or with procedures where a significant fire risk is present (e.g., when working

with open flame, etc.)

- Avoid wearing synthetic material clothing when working with any flammable, combustible,

explosive, or pyrophoric or self-heating materials.

- Synthetic clothing melts when on fire and will adhere to the skin.

- Avoid wearing synthetic material clothing when working with any flammable, combustible,

explosive, or pyrophoric or self-heating materials.

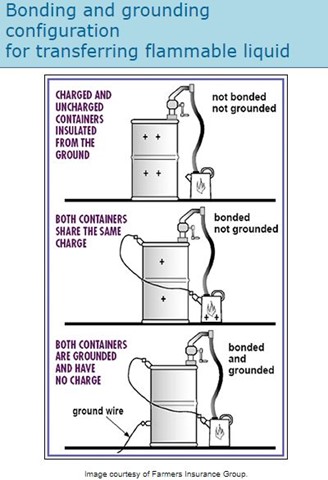

Bonding and Grounding

Bonding and grounding is defined as providing an electrically conductive pathway between a dispensing container, a receiving container and an earth ground. This pathway helps eliminate the buildup of static electricity by allowing it to safely dissipate into the ground.

Bonding refers to ensuring all components (containers, piping, pumps, funnels) in the dispensing process carry the same electrical potential.

Grounding is the process of carrying the electric charge to “earth” or “ground.” Indoor dispensing locations can tap into grounded building systems, such as the electrical distribution system, to carry the charge to ground.

For bonding and grounding to be effective, a metal-to-metal connection must be maintained between the bonding and grounding wires and the containers. To accomplish this, all paint, dirt, rust, etc., must be removed from the area of connection. These connections can be of two basic types: permanent or temporary. Permanent connections can be made by using solid or braided wires, and must incorporate either screw-type clamps, welding or other similar means. Temporary connections should use only braided wires in conjunction with spring clamps, magnetic clamps or other similar methods of maintaining metal-to-metal contact.

Quality of Grounding Source

Grounding is accomplished by attaching a ground cable to a ground rod or grounding system designed to provide a continuous ground path to less than 10 ohms (NFPA 77). The ground attachment must be metal-to-metal and must not be painted, and kept clean, free of debris or dirt to ensure a good connection. Grounding systems should be checked annually by an electrician to verify the ground resistance (contact RMS).

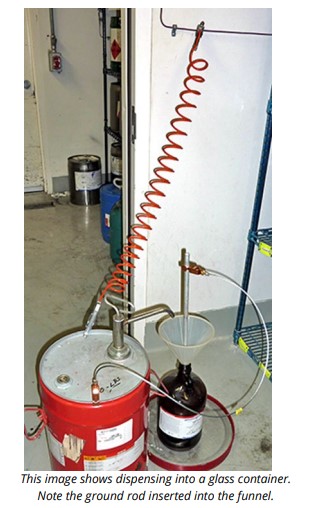

Dispensing into Plastic or Glass Container

Plastic and glass containers larger than 1.3 gallons should not be used for flammable liquid dispensing operations as these materials are non-conductive. Where there is a chemical compatibility issue and metal containers cannot be used, a metal funnel and fill pipe that extends to the bottom of the container or a metal rod inserted into the container can be used for bonding and grounding the operation.

Safety Can

Safety cans have a self-closing air tight lid, flexible metal dispensing nozzle and a flame arrestor that protects the contents from an external ignition source, making them safer for storage and dispensing of flammable liquids. However, bonding and grounding is still required when transferring flammable liquids because static electricity generation and accumulation is possible during the transfer. Polyethylene safety cans are equipped with a grounding lug designed to attach to ground wires.

Dispensing Location

Carefully assess and identify a safe location for flammable liquids transfer. Dispense flammable liquids (< 20 liters) inside a chemical fume hood or in a well-ventilated location. Flammable liquids in quantities > 20 liters must be dispensed inside a room/area specifically designed for dispensing flammable liquids with explosion-proof electrical wiring and equipment, and special ventilation systems. Contact RMS if you have questions. Ensure exit door and egress pathways are not obstructed in the dispensing location. Ensure all ignitions sources (e.g., flames, electrical outlets, etc.) are located at least 3 feet away from dispensing operations.